SUMMARY

DIAMOND CORE BIT – DIAMOND HOLE SAW

DIAMOND DRILLING – BLUE CERAM

CARBIDE HOLE SAW

DRILLING ROTATION SPEED – PRODUCT GUIDE

All our advice on use, safety and implementation to carry out all your holes.

DIAMOND CORE BIT

Use on a drilling machine (recommended speed 2500 rpm)

Implementation :

1/ Pre-drill with Ø8 on the desired depth.

2/ Fit the bit on the adapter and insert the centering guide.

3/ Place the centering guide with the bit in the pre-hole in order to begin coring.

4/ Drill to the desired depth.

DIAMOND HOLE SAW

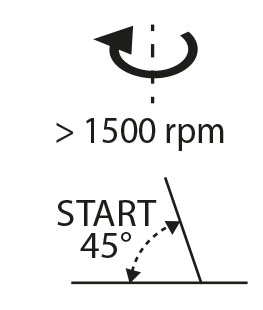

- Use on grinder (Recommanded drilling speed > 1500 rpm)

Start the drilling at 45°

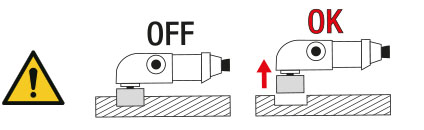

To avoid any risk of injury wait the complete stop of the machine before

removing the tool.

Assembly and disassembly diamond hole saw grinder or drill

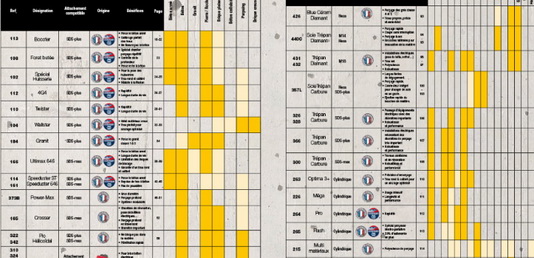

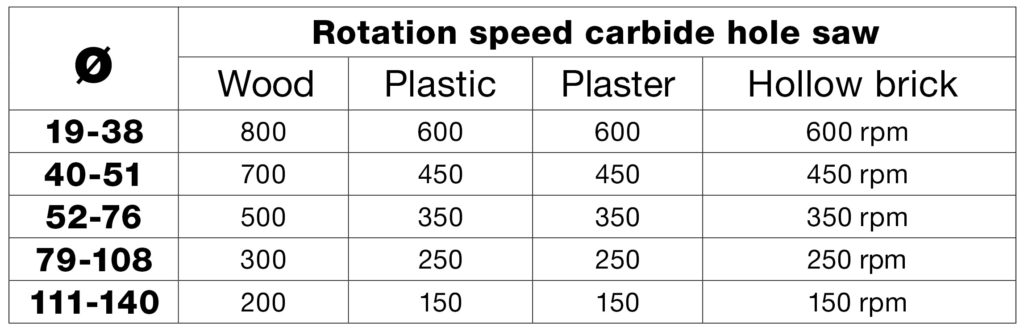

CARBIDE HOLE SAW

Adapt the rotational speed and the centring drill according to the material to be drilled

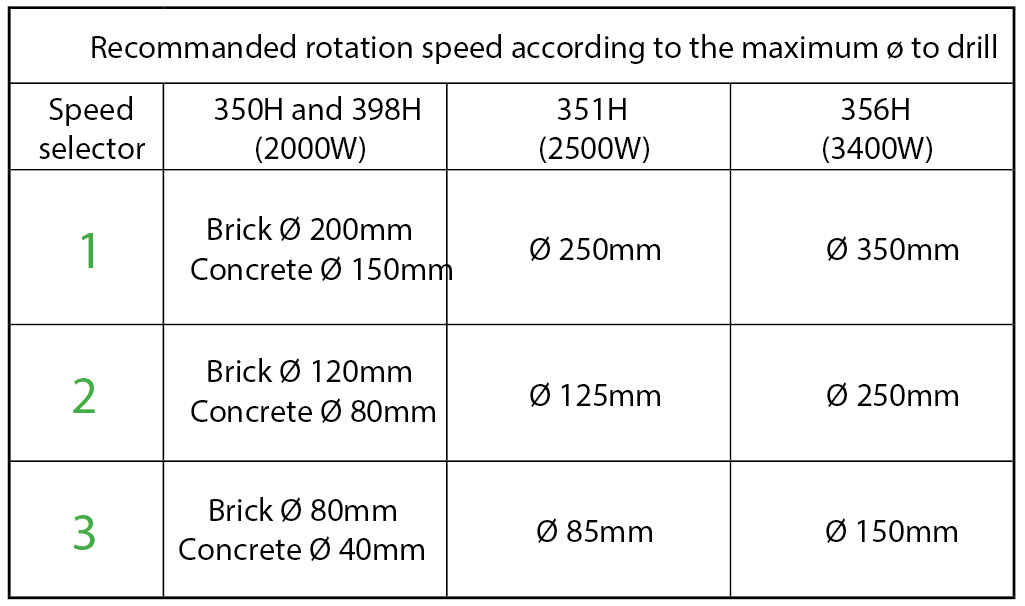

DIAMOND DRILLING

Manual drilling : ø 82 mm maximum.

After use : Let the machine run with no load for 1 minute.

Use 1 electric extension with a section of 3×4.5mm minimum.

An engine failure, a broken part, our after-sales service

ensures the repair and the supply of spare parts.

To obtain a quote or a support form,

contact our ADV department directly.

Phone number : +33 3 84 73 69 22 – Fax : +33 3 84 73 74 74

BLUE CERAM

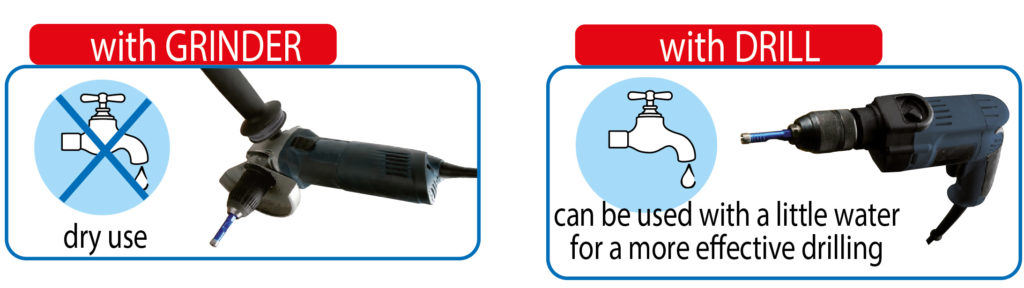

For dry use on angle grinder the chuck M14 is needed.

Remove the centring flange from the grinder before screwing on the chuck.

Can be use on a drilling machine without percussion.

For more efficency add a little water.

Start drilling at 45°.

1/ To avoid the sliding of the drill, start with an angle of 45°

2/ Once the drill bit is insidethe material, make sure the angle between the drill bit and the material reaches gradually 90°

3/ Make a swinging movement

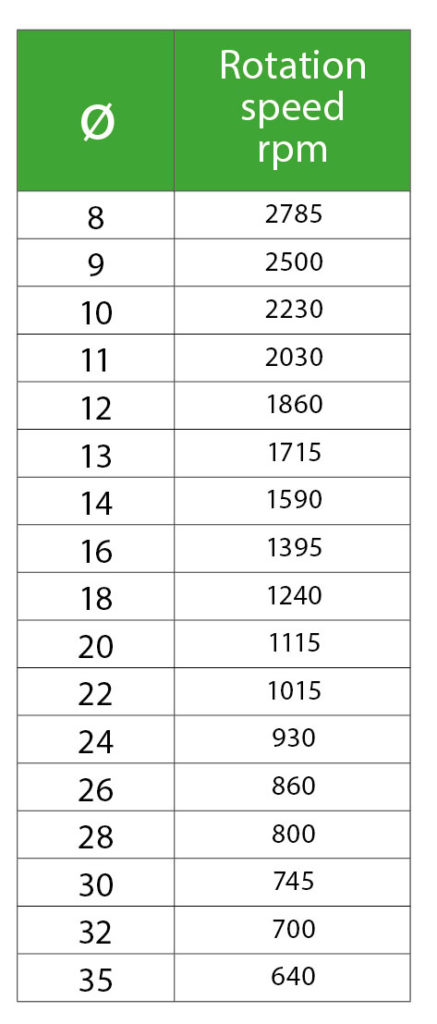

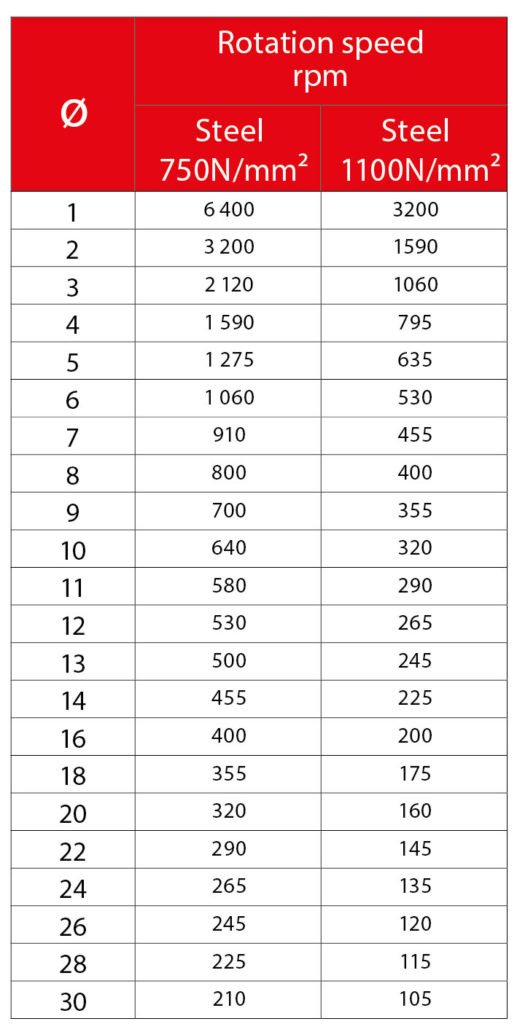

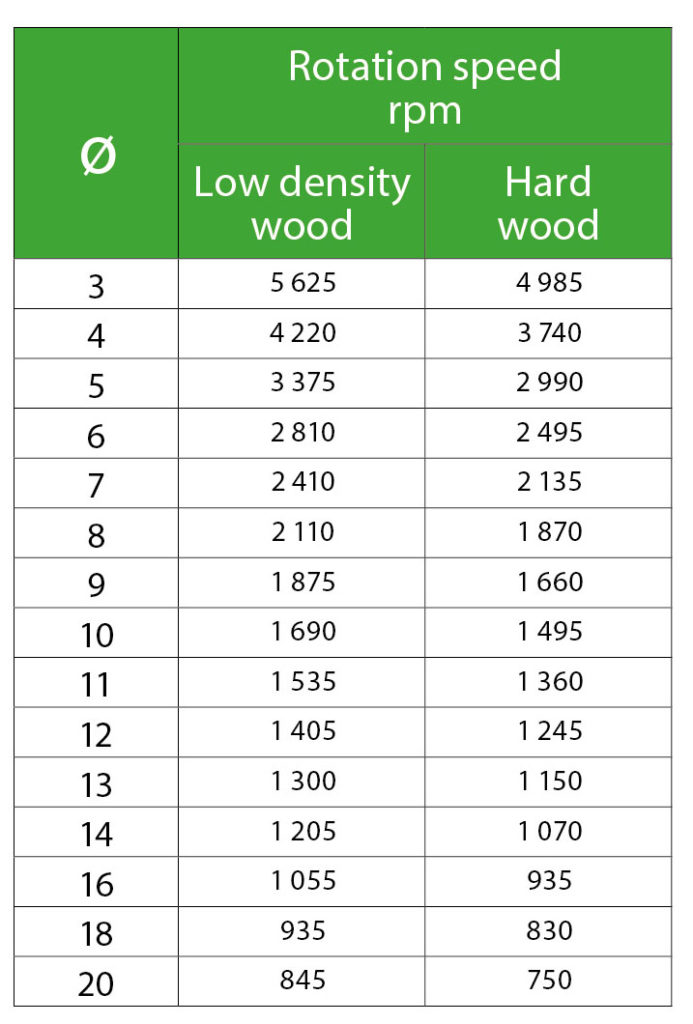

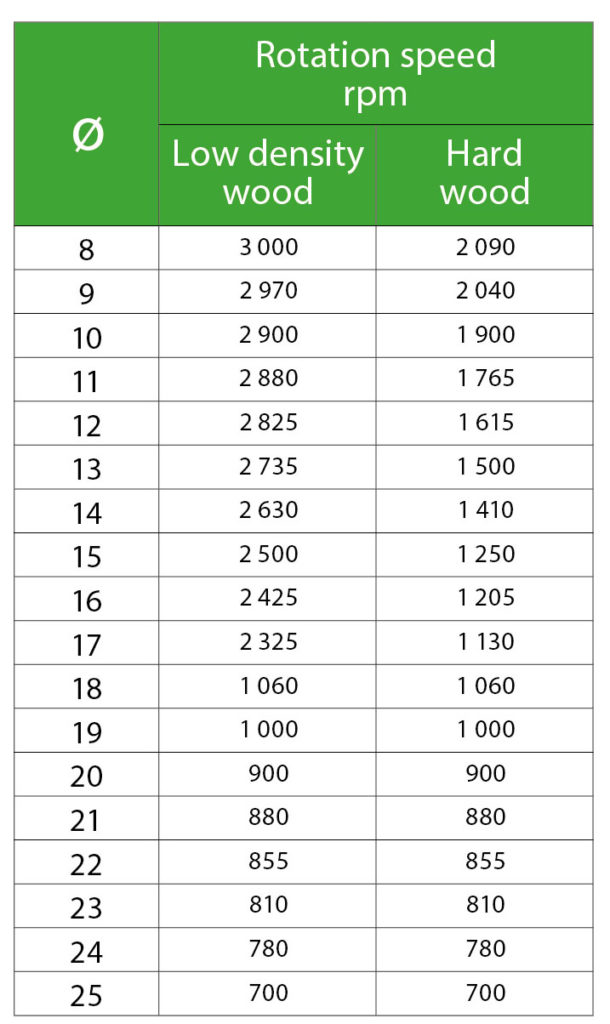

DRILLING ROTATION SPEED

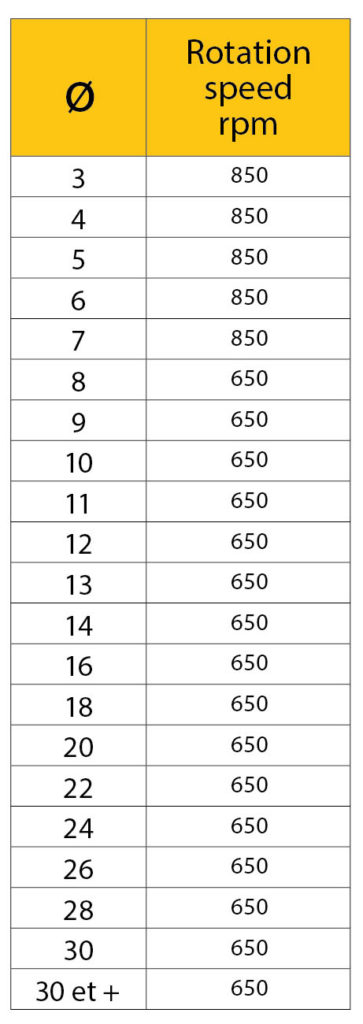

Hammer drill bit

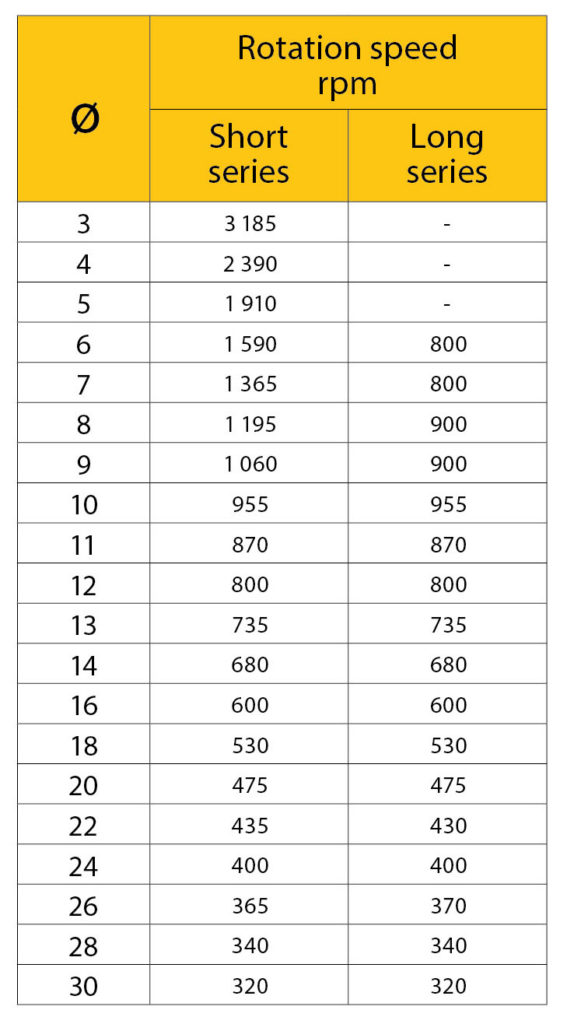

Drill bit

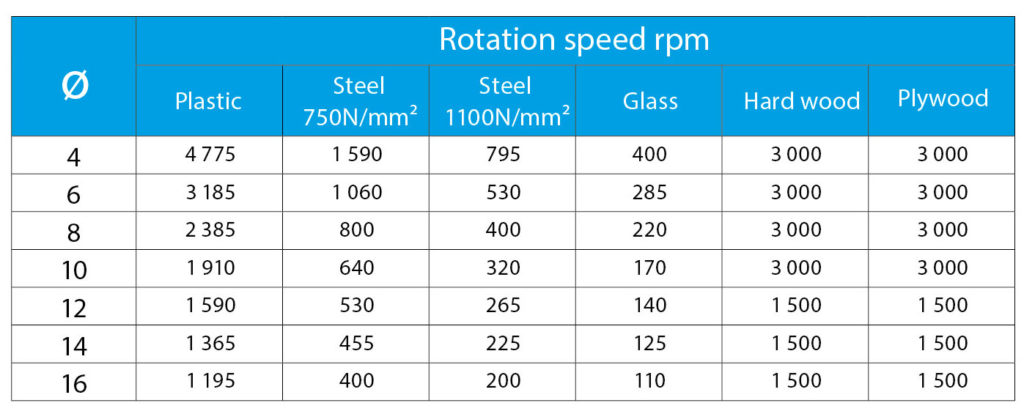

Multimaterials drill bit

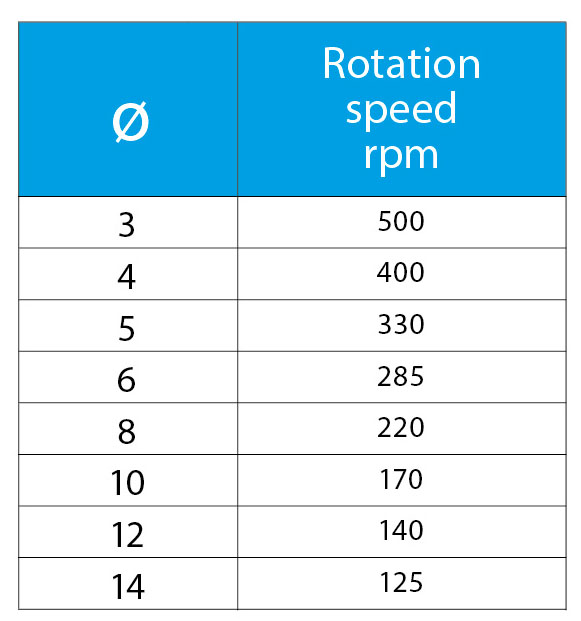

Glass drill bit

HSS drill bit

Wood drill bit

Auger drill bit

Flat drill bit